|

Our CC250 is a modified version of the CC170 and is specifically designed for irregular coding applications such as stacks of bags, chubs, parts and chipboard boxes.

|

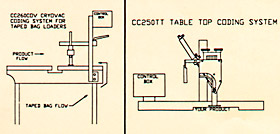

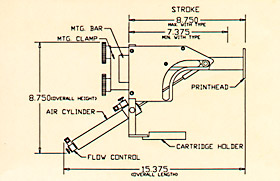

MODEL CC250 BACK The CC250 series is designed to imprint lot and expiration codes, pricing, code dates, logos, establishment numbers, productions codes and much more on irregular, hard to code products. We can help you meet HACCP requirements on primary and secondary packages. Whether you code Cryovac bags, flat or erected cartons or uneven parts, CCI can design an imprinting system to meet your needs.

|

||

|

|

|||

STANDARD FEATURES

|

APPLICATIONS Cryovac Taped Bag Loaders: Models 8055, 8155, 8177 & 8189 or stacks of individual bags Industrial Parts: Custom fixturing available Stacked Bags and Chipboard Boxes Irregularly Shaped Products We Have Manufactured Brackets For: Chub packed meats, speakers, motors, finished packages, caulking cartridge tubes, propane tanks, erected chipboard boxes and more.  Click here to see enlarged view  TOP BACK |

||